AKS Plasmatic

AKS Plasmatic

or

Call +1 314-283-1861

Description

Superior Quality Entry-Level Small Plasma Cutter

If you’re seeking a high-quality entry-level small plasma cutter, look no further than the PLASMATIC. Designed to deliver the highest level of accuracy with the lowest threshold for getting it up in running, this plug-and-play machine is ready to cut as soon as it’s connected to a power supply. AKS is backed by more than 100 years of machine-building experience and we’ve developed this streamlined small plasma cutter to serve your precise needs with the high-performance, high-quality machine you deserve.

Read on to explore the features of this entry-level small plasma cutter machine and contact us directly to see if this machine matches your needs.

If you’re seeking a high-quality entry-level small plasma cutter, look no further than the PLASMATIC. Designed to deliver the highest level of accuracy with the lowest threshold for getting it up in running, this plug-and-play machine is ready to cut as soon as it’s connected to a power supply. AKS is backed by more than 100 years of machine-building experience and we’ve developed this streamlined small plasma cutter to serve your precise needs with the high-performance, high-quality machine you deserve.

Read on to explore the features of this entry-level small plasma cutter machine and contact us directly to see if this machine matches your needs.

Features

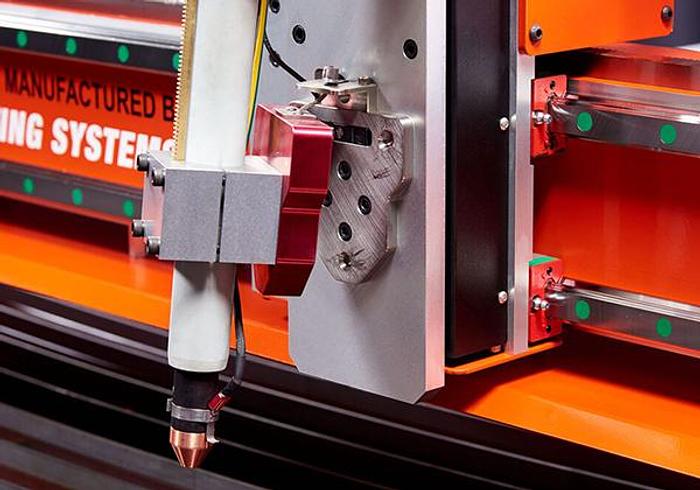

Advanced THC Lifter

Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This results in precise and high-quality cuts while also protecting the torch and extending consumable life.

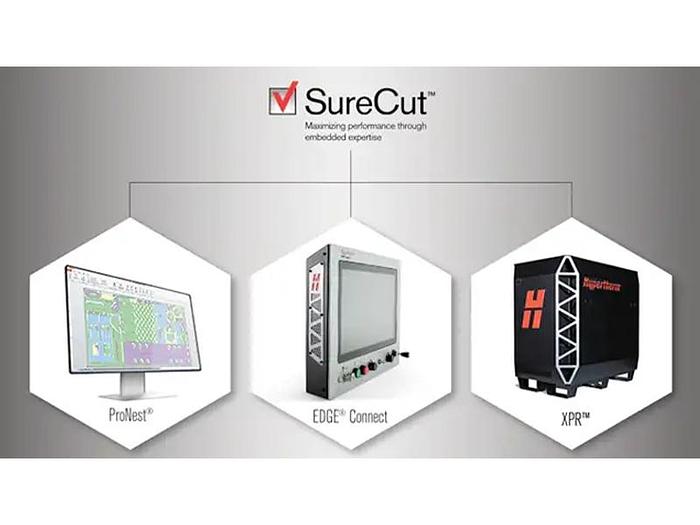

Hypertherm SureCut™ Technology

SureCut™ Technology automatically applies optimized cutting parameters, which simplifies cutting and reduces operator intervention.

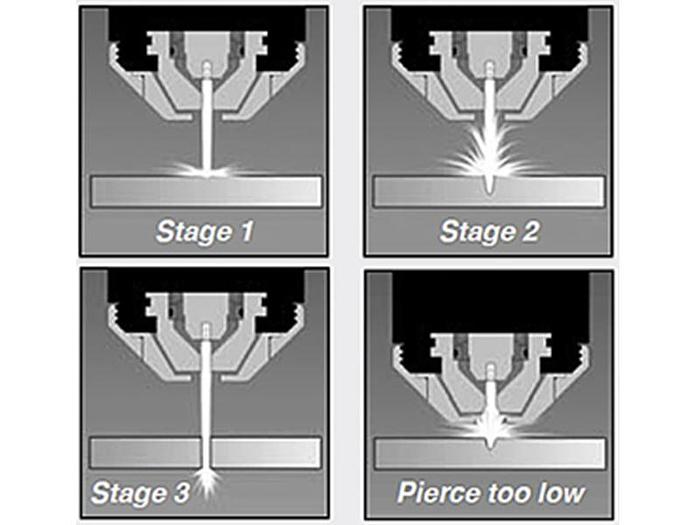

Torch Height Control (THC) Lifter

Utilizing Hypertherm Sensor technology, the torch height control lifter automatically controls torch height during the cutting process. It’s also fitted with a servo driven ball screw with arc voltage control system. This gives you more efficiency and safety in your operation.

Unitized Construction

Rigid and robust design ensures strength, productivity, and reliability, with performance and durability far exceeding less capable models.

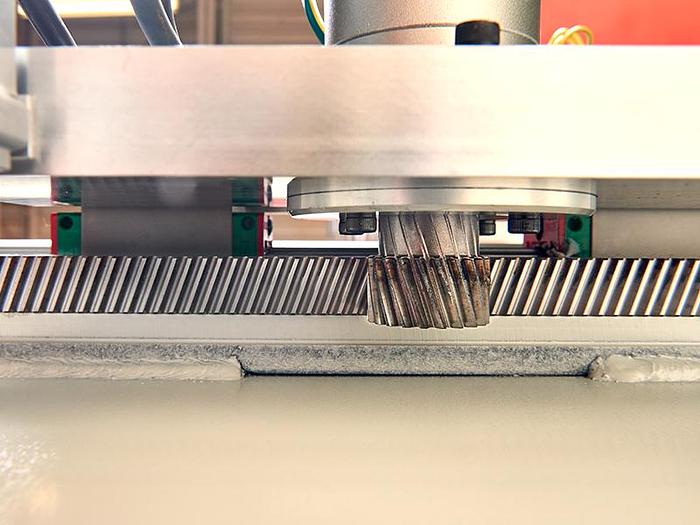

Helical Rack and Pinion Drives

The features X-axis and Y-axis helical rack and pinion drives. This configuration offers enhanced precision, increased load capacity, and more.

Replaceable Slat Table System

With a removable/replaceable slat table design, you can easily customize the table surface based on the material being cut, and replace worn-out slats when needed.

Magnetic Breakaway Head

The magnetic breakaway head protects plasma torch and machine from damage in case of collision or unintended contact with the workpiece.

Automatic Torch Height Control

Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This gives precise cuts while protecting the torch and extending consumable life.

Plug-and-Play Installation

Hook the unit up to a power supply and it’s ready to cut. No complex installation required.

Tucked Dual Rails

Precision linear rails are mounted on the machined surface and integrated with helical rack and pinion and precision bearings.

Advanced Helical Rack and Pinion Drive Systems

Features 12-foot X-axis dual synchronized drives with helical rack and pinion. It also has a 6-foot Y-axis bridge single drive with helical rack and pinion. This configuration allows for precise motion control, increased stability, and high-speed cutting.

Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This results in precise and high-quality cuts while also protecting the torch and extending consumable life.

SureCut™ Technology automatically applies optimized cutting parameters, which simplifies cutting and reduces operator intervention.

Utilizing Hypertherm Sensor technology, the torch height control lifter automatically controls torch height during the cutting process. It’s also fitted with a servo driven ball screw with arc voltage control system. This gives you more efficiency and safety in your operation.

Rigid and robust design ensures strength, productivity, and reliability, with performance and durability far exceeding less capable models.

The features X-axis and Y-axis helical rack and pinion drives. This configuration offers enhanced precision, increased load capacity, and more.

With a removable/replaceable slat table design, you can easily customize the table surface based on the material being cut, and replace worn-out slats when needed.

The magnetic breakaway head protects plasma torch and machine from damage in case of collision or unintended contact with the workpiece.

Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This gives precise cuts while protecting the torch and extending consumable life.

Hook the unit up to a power supply and it’s ready to cut. No complex installation required.

Precision linear rails are mounted on the machined surface and integrated with helical rack and pinion and precision bearings.

Features 12-foot X-axis dual synchronized drives with helical rack and pinion. It also has a 6-foot Y-axis bridge single drive with helical rack and pinion. This configuration allows for precise motion control, increased stability, and high-speed cutting.

The PLASMATIC features either a water or downdraft table, depending on what your operation needs. Both of these options can help reduce smoke, dust, and noise, which creates a more positive work environment.

With multiple table sizes to choose from, you can customize the PLASMATIC to fit your needs. The machine comes in 5×10 and 6×12 options.

Accessories

Plasma Quench

Our plasma quench additive is a rust inhibitor that you can add to your water table. It’s also great for reducing odor and bacteria within your machine.

Air Scribe Marking System

With our air scribe marking system, you can create clear and precise marks, which promotes cleaner cuts and reduced downtime.

Air Bubbler System

The air bubbler system is crucial if you’re cutting aluminum. Cutting aluminum adds hydrogen bubbles, which can damage the cutting material. The air bubbler system removes these bubbles for a cleaner result.

Roller Ball Lifter Unit

Are you cutting thin gauge material? Then you need the roller ball lifter unit. This technology holds down the material and promotes more accurate cuts.

Our plasma quench additive is a rust inhibitor that you can add to your water table. It’s also great for reducing odor and bacteria within your machine.

With our air scribe marking system, you can create clear and precise marks, which promotes cleaner cuts and reduced downtime.

The air bubbler system is crucial if you’re cutting aluminum. Cutting aluminum adds hydrogen bubbles, which can damage the cutting material. The air bubbler system removes these bubbles for a cleaner result.

Are you cutting thin gauge material? Then you need the roller ball lifter unit. This technology holds down the material and promotes more accurate cuts.

The PLASMATIC features ProNest 2025 part nesting software for advanced mechanized cutting. It’s designed to help you achieve greater automation, efficiency, and profitability. The machine can also run Shop Data Systems, an HVAC software package for anyone completing duct work. But those aren’t the only software packages the PLASMATIC runs. It also features FlashCut Smart 360 — an advanced hole cutting add-on that gives you bolt-quality holes.

The PLASMATIC also features an industrial panel operator console. This technology provides a centralized point of control, monitoring, and adjustment for various aspects of the plasma cutting process.

Additionally, the PLASMATIC has a motion system that allows for the highest accuracy, smoothest motion, and lowest noise output in its class. Its single-set-up machined milled surfaces allow for precision mounting of helical racks. It also has precision ground linear bearings. Additionally, it features precision pinions driven by dual-side planetary gearboxes and industrial stepper motors, without forced engagement from pneumatic or spring-load operations.

The PLASMATIC features three-day onsite installation and training by a certified AKS technician. This can be completed by an authorized installer or by the customer.

The AKS new machine warranty covers parts and labor. See terms for more information.

Participation in our Elite Edge Customer Success Program offers cost savings on Hypertherm consumables and AKS service.

Our team covers all your service and cutting support needs. Must purchase Hypertherm consumables from AKS Cutting Systems to be eligible.

Specifications

| Manufacturer | AKS |

| Condition | New |

| Mation Accuracy | +/- 0.010” per 3 feet of motion |

| Travel Speed | 800 ipm |

| Screen Size | 19-inch touchscreen with keyboard and mouse |

| Max Cut Depth | 1.25 inches |

| Max Cut Width | Up to 6 feet |

| Max Cut Length | Up to 12 feet |