AKS Dura-Kut

AKS Dura-Kut

Description

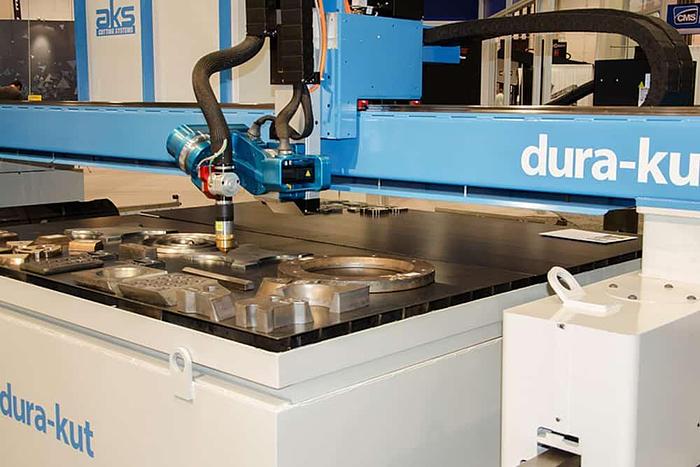

Industrial Plasma Cutter Perfect for Large, Thick Plate Applications Looking for an industrial plasma cutter for large, thick cutting applications? Turn to the dura-kut. It’s manufactured to machine tool standards and is built for maximum precision, repeatability, flexibility, durability, and longevity. Using the latest precision drive systems, it delivers high-speed, high-accuracy, heavy-duty plasma cutting.

As with all of our machines, the dura-kut is highly customizable. We offer countless tools, features, and options to ensure our machines fit our clients’ needs. However, your operation may not need all of these options. That’s why it’s important to talk to a member of our team. We’ll listen to your requirements and match you with the right system. Contact us today to get started.

See our Premium Accessories for dura-kut Looking for an industrial plasma cutter for large, thick cutting applications? Turn to the dura-kut. It’s manufactured to machine tool standards and is built for maximum precision, repeatability, flexibility, durability, and longevity. Using the latest precision drive systems, it delivers high-speed, high-accuracy, heavy-duty plasma cutting. As with all of our machines, the dura-kut is highly customizable. We offer countless tools, features, and options to ensure our machines fit our clients’ needs. However, your operation may not need all of these options. That’s why it’s important to talk to a member of our team. We’ll listen to your requirements and match you with the right system. Contact us today to get started.

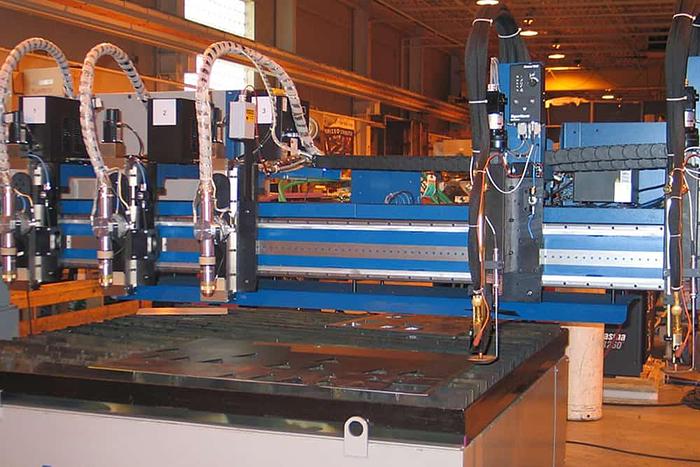

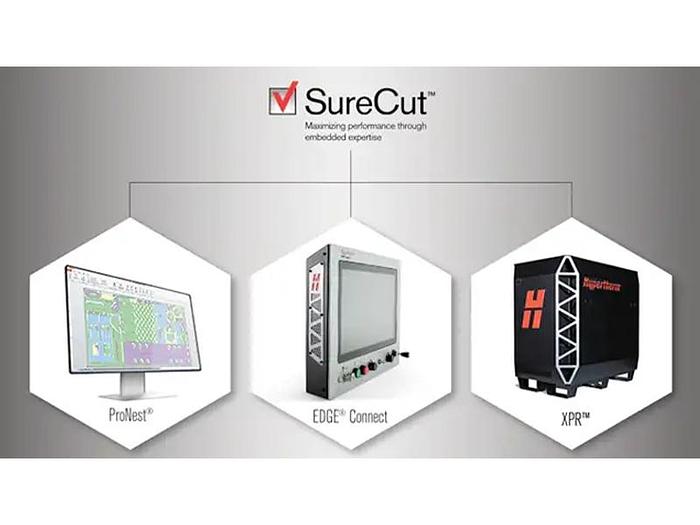

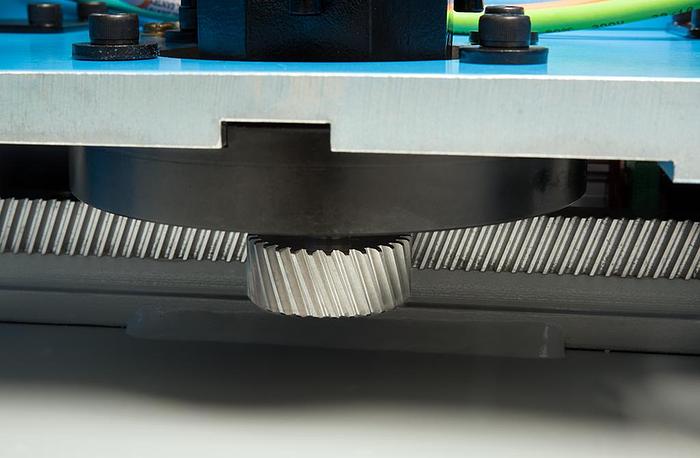

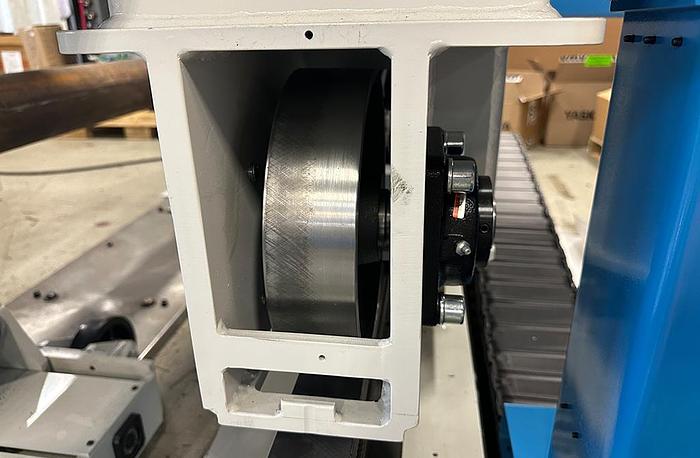

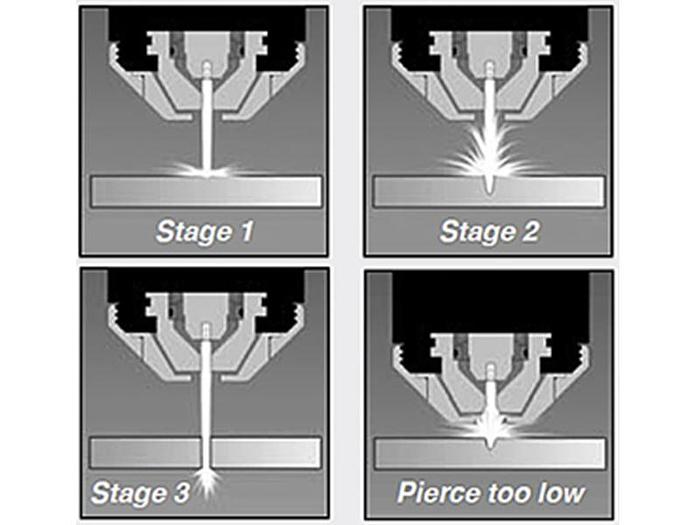

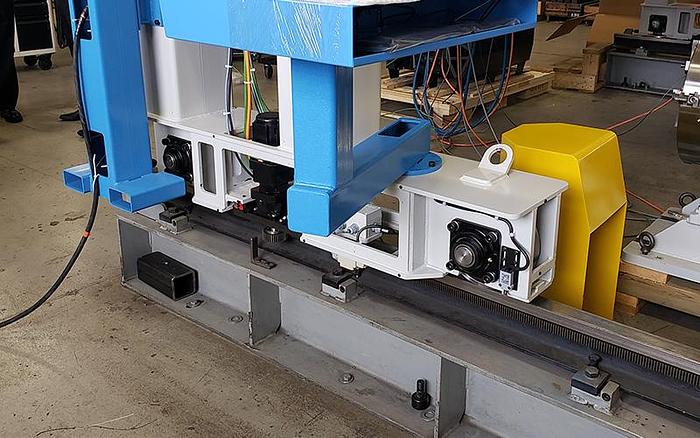

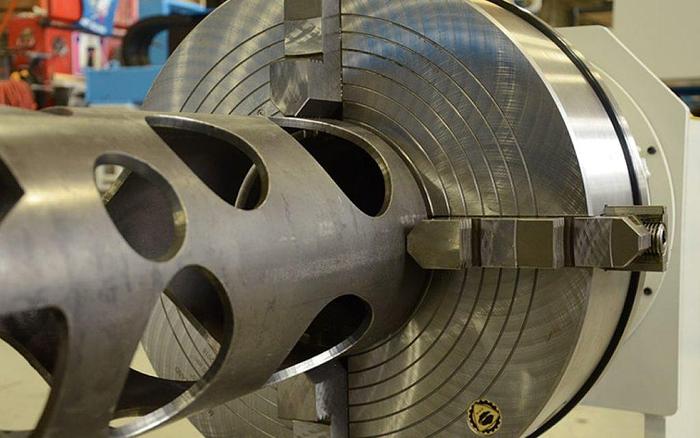

Features Advanced THC Lifter Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This results in precise and high-quality cuts while also protecting the torch and extending consumable life. Hypertherm SureCut™ Technology SureCut™ Technology automatically applies optimized cutting parameters, which simplifies cutting and reduces operator intervention. Hypertherm Edge Connect CNC Controller The Edge Connect CNC controller enhances overall system reliability, improves cut quality, and increases productivity for your operation. Standard Hy-Definition Torch With a hy-definition torch, you can achieve high-quality, high-precision cuts in various metal thicknesses. Gantry-Style Bridge Features greater support, stability, and accuracy due to its gantry-style bridge. You can expect greater speed and efficiency, along with better-quality parts. Direct Pinion Loading With direct pinion loading, you can minimize backlash and reduce the potential for positioning errors. This is crucial for maintaining high precision in plasma cutting operations, where even small deviations can lead to significant inaccuracies in the final cut Oversized Wheel Bearings The dura-kut’s oversized wheel bearings allow for enhanced load bearing capacity, improved stability and precision, and more benefits. Multiple Plasma or Oxy-Fuel Cutting Torches Adding multiple cutting torches increases productivity and reduces downtime. While the initial investment for additional torches may be higher, the increased efficiency and productivity can lead to long-term cost savings by reducing labor costs. Marking and Etching Technology The dura-kut makes it easy to mark bendlines, weld points, or any other shape, which optimizes your operations. Any AKS system can utilize argon/nitrogen marking, pin stamping, or air scribe technology. Automatic Torch Height Control Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This gives precise cuts while protecting the torch and extending consumable life. Plug-and-Play Installation Hook the unit up to a power supply and it’s ready to cut. No complex installation required. Magnetic Breakaway Head The magnetic breakaway head protects plasma torch and machine from damage in case of collision or unintended contact with the workpiece. Advanced Helical Rack and Pinion Drive Systems Dual Drive vertical tooth rack and pinion mounted to 107lbs crane rail allow near infinite lengths and highly customizable widths regardless of floor flatness. Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This results in precise and high-quality cuts while also protecting the torch and extending consumable life. SureCut™ Technology automatically applies optimized cutting parameters, which simplifies cutting and reduces operator intervention. The Edge Connect CNC controller enhances overall system reliability, improves cut quality, and increases productivity for your operation. With a hy-definition torch, you can achieve high-quality, high-precision cuts in various metal thicknesses. Features greater support, stability, and accuracy due to its gantry-style bridge. You can expect greater speed and efficiency, along with better-quality parts. With direct pinion loading, you can minimize backlash and reduce the potential for positioning errors. This is crucial for maintaining high precision in plasma cutting operations, where even small deviations can lead to significant inaccuracies in the final cut The dura-kut’s oversized wheel bearings allow for enhanced load bearing capacity, improved stability and precision, and more benefits. Adding multiple cutting torches increases productivity and reduces downtime. While the initial investment for additional torches may be higher, the increased efficiency and productivity can lead to long-term cost savings by reducing labor costs. The dura-kut makes it easy to mark bendlines, weld points, or any other shape, which optimizes your operations. Any AKS system can utilize argon/nitrogen marking, pin stamping, or air scribe technology. Our advanced torch height control (THC) lifter helps maintain a consistent and optimal distance between the torch and workpiece. This gives precise cuts while protecting the torch and extending consumable life. Hook the unit up to a power supply and it’s ready to cut. No complex installation required. The magnetic breakaway head protects plasma torch and machine from damage in case of collision or unintended contact with the workpiece. Dual Drive vertical tooth rack and pinion mounted to 107lbs crane rail allow near infinite lengths and highly customizable widths regardless of floor flatness. Get enhanced precision, stability, and operator safety with an H-beam support. The dura-kut offers customizable table sizes, which means maximum convenience for your business. These tables are available from multiple third parties or the AKS team. Standard widths range from 8 feet to 18 feet. Dura-max widths range from 18 feet to 30 feet. Length range in 10-foot increments up to 200 feet. Experience a cleaner workspace with a downdraft table add-on. The following accessories further promote cleanliness. Our imperial dust collector — model CM04 — gathers airborne dust and particles. Our dust drum level sensor prevents dust overflow. Additionally, our HEPA filter increases air filtration efficiency and particle capture. We also have cold weather solenoid kits to prevent freezing and operational issues Save time and streamline production with our self-cleaning table option. The self-cleaning downdraft table automatically sweeps out excess slag, scrap, waste, and even small parts. Slag collection pans can roll in and out under the drive unit cabinet. This allows for easy dumping, requiring no pits or holes cut into the floor. Upgrading to a water table can result in a cleaner workspace, improved material cooling, enhanced precision, noise reduction, and more. We offer a complete steel structure water tank design with removable/replaceable steel slats. Removable scrap pans are optional and easy-to-clean while keeping the table in production. Premium Accessories tube-kut Save space and money with the tube-kut add-on system. This technology increases processing flexibility and versatility to handle both flat plate cutting and tube/pipe cutting. It’s much smaller and costs less than dedicated pipe and tube cutting systems. The tube-kut is positioned on the floor of the dura-kut, either on the left or right hand side of the table, and is operated by the CNC controller. With an integrated servo-controlled sixth-axis rotary drive, it automatically rotates and indexes the tube/pipe, via a headstock chuck, as the plasma torch cuts shapes and profiles in the tube wall. robo-kut The robo-kut is the most powerful plasma cutting 5-axis bevel head in the industry. It’s capable of +/- 45 degrees for A, V, K, X, top-Y, and bottom-Y style bevel cuts for weld prep applications, countersinks, and chamfers. It’s also capable of precision taper compensation or back-beveling. This technology can produce a 0.5-inch diameter bolt-ready hole in a 1-inch thick steel plate. This results in a 0.5:1 ratio for hole diameter: thickness. Competitive machines are limited to a traditional 1:1 ratio. The robo-kut performs continuous unlimited rotation without interruption. This means it can cut the most complex 5-axis parts without having to stop and unwind. It also includes a magnetic torch breakaway head to prevent damage upon a crash. Additional Accessories Wireless Remote Control Pendant Featuring a digital camera and on-screen crosshair, this equipment allows for easy machine setup and more accurate cuts. Drill Attachment Streamline drilling operations by adding a drill attachment to your tru-kut machine. Adding this technology can dramatically reduce costly downtime. Pin Stamping Features an optional pin stamping technology that makes it easy to create permanent marks or characters on the material. Save space and money with the tube-kut add-on system. This technology increases processing flexibility and versatility to handle both flat plate cutting and tube/pipe cutting. It’s much smaller and costs less than dedicated pipe and tube cutting systems. The tube-kut is positioned on the floor of the dura-kut, either on the left or right hand side of the table, and is operated by the CNC controller. With an integrated servo-controlled sixth-axis rotary drive, it automatically rotates and indexes the tube/pipe, via a headstock chuck, as the plasma torch cuts shapes and profiles in the tube wall. The robo-kut is the most powerful plasma cutting 5-axis bevel head in the industry. It’s capable of +/- 45 degrees for A, V, K, X, top-Y, and bottom-Y style bevel cuts for weld prep applications, countersinks, and chamfers. It’s also capable of precision taper compensation or back-beveling. This technology can produce a 0.5-inch diameter bolt-ready hole in a 1-inch thick steel plate. This results in a 0.5:1 ratio for hole diameter: thickness. Competitive machines are limited to a traditional 1:1 ratio. The robo-kut performs continuous unlimited rotation without interruption. This means it can cut the most complex 5-axis parts without having to stop and unwind. It also includes a magnetic torch breakaway head to prevent damage upon a crash. Featuring a digital camera and on-screen crosshair, this equipment allows for easy machine setup and more accurate cuts. Streamline drilling operations by adding a drill attachment to your tru-kut machine. Adding this technology can dramatically reduce costly downtime. Features an optional pin stamping technology that makes it easy to create permanent marks or characters on the material. AKS Cutting Systems is the only company that provides the full suite of Hypertherm SureCut technology options. SureCut maximizes performance by providing embedded expertise from a combination of tools. These tools include state-of-the-art plasma power supplies, along with CNC and CAM software. SureCut automatically applies optimized cutting parameters, which simplifies cutting and reduces operator intervention. With the ability to work across multiple cutting technologies, SureCut improves job efficiency. You also get access to remote help if you need to troubleshoot, which reduces downtime in your operation. It’s a game-changer for industrial plasma cutter operations. The SureCut suite of tools includes: True Hole for mild steel produces significantly better hole quality than traditional plasma technology. Factory tested and easily implemented, True Bevel takes the guesswork out of the plasma bevel cutting process. Rapid Part controls and optimizes every step in the plasma cutting process, which reduces cut-to-cut cycle time. Sensor Torch Height Control is a CNC-integrated system that provides optimized plasma cut performance and reliability. ProNest CAD/CAM part nesting software helps you achieve greater automation, efficiency, and profitability. Save time and take stress off your plate with our fast installation services. The five-day installation process includes onsite installation and training by a certified AKS technician. Our warranty covers parts and labor for new AKS machines. Speak to one of our team members to see terms and conditions. All AKS customers are eligible to participate in our Elite Edge Customer Success Program. This program provides discounts on AKS service, consumables, and more. AKS customers get lifetime phone support for all service and cutting needs. Must purchase Hypertherm™ consumables from AKS Cutting Systems to be eligible.

Specifications

| Manufacturer | AKS |

| Condition | New |

| Motion Accuracy | +/- 0.006-inch per 3-feet accuracy of motion |

| Travel Speed | 1200 ipm travel speed |

| Screen Size | 19” color touch screen console |

| Max Cut Depth | Up to 16 inches |

| Max Cut Width | Up to 30 feet |

| Max Cut Length | Up to 200 feet in 10-foot increments |